product

Home>>Shuttle loom

Details

Usage

1.The machine is used to process the card sliver, drawing sliver, or comb sliver produced in spinning process of cotton, wool, and chemical fiber etc. These slivers, after fixing constant length, and continuously pulling-apart at high-speed, are supplied for direct reclamation of package, dyeing, and mixing, etc.

2.Comb slivers, before direct dyeing process, are pulled apart in constant length on the machine, which is a necessary key equipment in the new technology of spinning high quality and top grade fiber dyed yarn.

3.Matched with a reciprocating bale plucker, the machine is used as a reusable cotton waste feeder, which is an auxiliary equipment in blowing-carding production line.

4.The machine can pull apart slivers in constant length(≤100mm)to package them for the use of reciprocating or disc bale plucker, which can thoroughly solve the difficult problem of too long cotton silvers twining round the beater, and to get even more fine&uniform plucking.

Structural characteristics of the machine

1.The active sliver-guiding installation is adopted

2.By means of the forming of high-power drafting, tens of cotton slivers are in progress of fixing lenght and pulling-apart continuiously, quickly, and uniformly.

3.A protection device is fitted on this machine for thick cotton sliver auto-stop

4.The machine possesses an auto output device, which is in use matched with a reciprocating bale plucker. With a suction funnel, cotton slivers are sucked out by a fan and then feed into a cotton mixer.Specifications

Output (kg/h) 110-300

Suitable for fiber material cotton, wool, chemical fiber(≤76mm)

Working width(rnm) 340

Speed of delivery roller(m/min) 239

Fixed length of pulling-apart(mm) ≤100

Number of feed slivers (pcs) 16-60

Applicable condition It can be used in single or matched width a blowing carding line

power (kw) 1.5

Overall dimensions (LxWxH, mm) 1600*920*1370

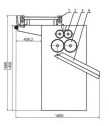

1. Pressing sliver roller conjunction

2. Upper squeezing roller conjunction

3. Lower squeezing roller conjunction

4. Sliver transport lattice【Print this page 】 【close】